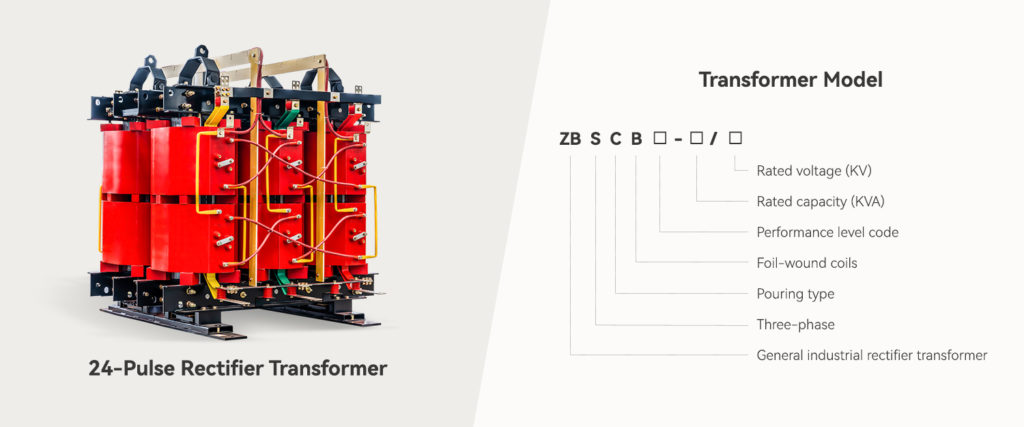

Voltron 24-Pulse Rectifier Dry-Type Transformer

Brand: Voltron Type: Dry-Type Transformer Rated Capacity: 200kVA-2500kVA Vector Group: Dyn11, Yyn0, Dd0 Winding Type: Multi-winding Phase: Three-Phase Service: Customized Service Nature of Business: Manufacturer

1. Safety and Reliability: The transformer is constructed using non-toxic, flame-retardant epoxy resin, offering high mechanical strength, flame resistance, fire prevention, and environmental friendliness.

2. Convenient Installation: Dry-type rectifier transformers are delivered as complete units, allowing for immediate installation and efficient operation.

3. High Overload Capacity: The transformer’s insulation is rated at class H , with a heat resistance temperature reaching 180°C. It can handle maximum overloads of up to 200%.

4. Low Noise: Noise levels are reduced by 3-5 decibels compared to national standards.

5. Cost Savings: Dry-type rectifier transformers can be installed in conjunction with electrical equipment such as rectifiers, eliminating the need for a separately designed distribution room. This saves space and reduces initial investments.

6. Diverse Range: Our product offerings are comprehensive, covering specialized transformers in various fields, including rectifier transformers, electric furnace transformers, and variable frequency transformers.

7. Tailor-Made Solutions: We can accommodate specific customer requirements, offering flexible design and rapid responses.

8. Authoritative Certification: Our products have received authoritative certification from the National Electrical Product Quality Supervision and Inspection Center.

24-Pulse Rectifier Dry-Type Transformer | |||||||||

Model | Capacity(KVA) | Rated Voltage(KV) | Tapping Range | Vector Group | Short Circuit Impedance | Efficiency | Weight(kg) | Gauge(mm) | |

Net Side | Valve Side | ||||||||

ZBSCB10 | 200 | 10 | 0.4 | 2*2.5% | Dyn11 | 4.0 | ≥0.97 | 1250 | 550 x 550 |

ZBSCB10 | 250 | 4.0 | ≥0.97 | 1430 | 550 x 550 | ||||

ZBSCB10 | 315 | 4.0 | ≥0.97 | 1570 | 660 x 660 | ||||

ZBSCB10 | 400 | 4.0 | ≥0.98 | 1750 | 660 x 660 | ||||

ZBSCB10 | 500 | 4.0 | ≥0.98 | 1970 | 820 x 820 | ||||

ZBSCB10 | 630 | 6.0 | ≥0.98 | 2250 | 820 x 820 | ||||

ZBSCB10 | 800 | 6.0 | ≥0.98 | 2590 | 820 x 820 | ||||

ZBSCB10 | 1000 | 6.0 | ≥0.98 | 2940 | 820 x 820 | ||||

ZBSCB10 | 1250 | 6.0 | ≥0.98 | 3420 | 820 x 820 | ||||

ZBSCB10 | 1600 | 6.0 | ≥0.98 | 3830 | 820 x 820 | ||||

ZBSCB10 | 2000 | 6.0 | ≥0.99 | 4500 | 820 x 820 | ||||

ZBSCB10 | 2500 | 6.0 | ≥0.99 | 5350 | 820 x 820 | ||||

ZBSCB10 | 500 | 35 | 6.0 | ≥0.98 | 2680 | 820 x 820 | |||

ZBSCB10 | 630 | 6.0 | ≥0.98 | 3300 | 820 x 820 | ||||

ZBSCB10 | 800 | 6.0 | ≥0.98 | 3810 | 820 x 820 | ||||

ZBSCB10 | 1000 | 6.0 | ≥0.98 | 4650 | 1070 x 1070 | ||||

ZBSCB10 | 1250 | 6.0 | ≥0.98 | 5250 | 1070 x 1070 | ||||

ZBSCB10 | 1600 | 6.0 | ≥0.98 | 5750 | 1070 x 1070 | ||||

ZBSCB10 | 2000 | 6.0 | ≥0.99 | 6380 | 1070 x 1070 | ||||

ZBSCB10 | 2500 | 6.0 | ≥0.99 | 7390 | 1070 x 1070 | ||||

Voltron produces marine and offshore platform transformers with low voltage (1kV) and medium voltage (10kV). Our transformer products have obtained Product Type Approval from CCS (China Classification Society) and Factory Approval from BV (Bureau Veritas). Voltron can provide product certificates from major classification societies, including CCS, ABS, DNV-GL, BV, LR, RINA, and NK.

In 2001, Voltron signed a strategic cooperation agreement with DuPont, leveraging DuPont’s advanced and mature RAY-LITE transformer core technology. The open-type transformers produced by Voltron have consistently held a leading position in the industry.

In 2010, on the occasion of Voltron ‘s 20th anniversary, the company once again collaborated with DuPont, signing a trademark licensing agreement for the DuPont NOMEX brand. In the future, the DuPont NOMEX insulation system will be applied across the entire product range at Voltron , marking a new beginning in the brand alliance between Voltron and DuPont.

In 2020, Voltron and DuPont signed another strategic cooperation agreement, commemorated with a signing ceremony in Yangzhong Linjiang Industrial Park.

1. Reliability of Insulation Technology

Our research spans from initial two-dimensional electric field simulations, three-dimensional electric field measurements, and impact characteristic measurements to later-stage theoretical analysis and simulated experiments on the main insulation, longitudinal insulation, end insulation, insulation of leads, and coil withstand voltage characteristics of transformers. Through years of verification using various methods, we ensure the reliability of transformer insulation.

2. Calculation of leakage magnetic field and reduction of stray loss

Dedicate specialized efforts to calculating and measuring transformer leakage magnetic fields. The research includes shielding structures for leakage magnetic fields, calculations for transformer dynamics and thermal stability, and improvements in transformer dynamic and thermal stability to guarantee accurate calculations and reduce stray losses, enhancing transformer dynamic stability.

3. Precise Analysis of Coil Temperature Fields

Collaborating with numerous domestic universities, we jointly developed programs for calculating coil temperature fields. These programs calculate loss distribution in coils, including resistive losses, eddy current losses in different directions, circulating losses between parallel conductors, and flow field cooling conditions. This enables the accurate calculation of coil temperature distribution and hotspot temperature rises, allowing us to take measures to control hotspot temperature effectively rises that impact transformer lifespan.

4. Reducing Local Discharge in Transformers

Electric field strengths at various locations have undergone numerical analysis during the design phase and have been strictly controlled. Additionally, compliance with manufacturing quality, the reliability of processing methods, and the reasonableness of operating techniques effectively control local discharges in transformers.